Sheet Metal Fabrication

Sheet Metal Fabrication offers rapid prototyping, customization, reduced time-to-market, cost-effectiveness, complex geometries, and sustainability.

Sheet Metal Fabrication Processes

Sheet Metal Fabrication Services Materials

- Aluminium

- Copper

- Nickel

- Mild Steel

- Stainless Steel

What is Sheet Metal Fabrication? Why us?

We offer comprehensive sheet metal services that include various cutting operations to meet your specific needs. Here are the highlighted bullet points for each cutting operation:

Sheet Cutting Services:

– Specialize in precise and accurate cutting of sheet metal materials.

– Utilize advanced cutting techniques for clean and burr-free edges.

– Capable of cutting various metals, including stainless steel, aluminum, and mild steel.

– Offer high-speed cutting for efficient production.

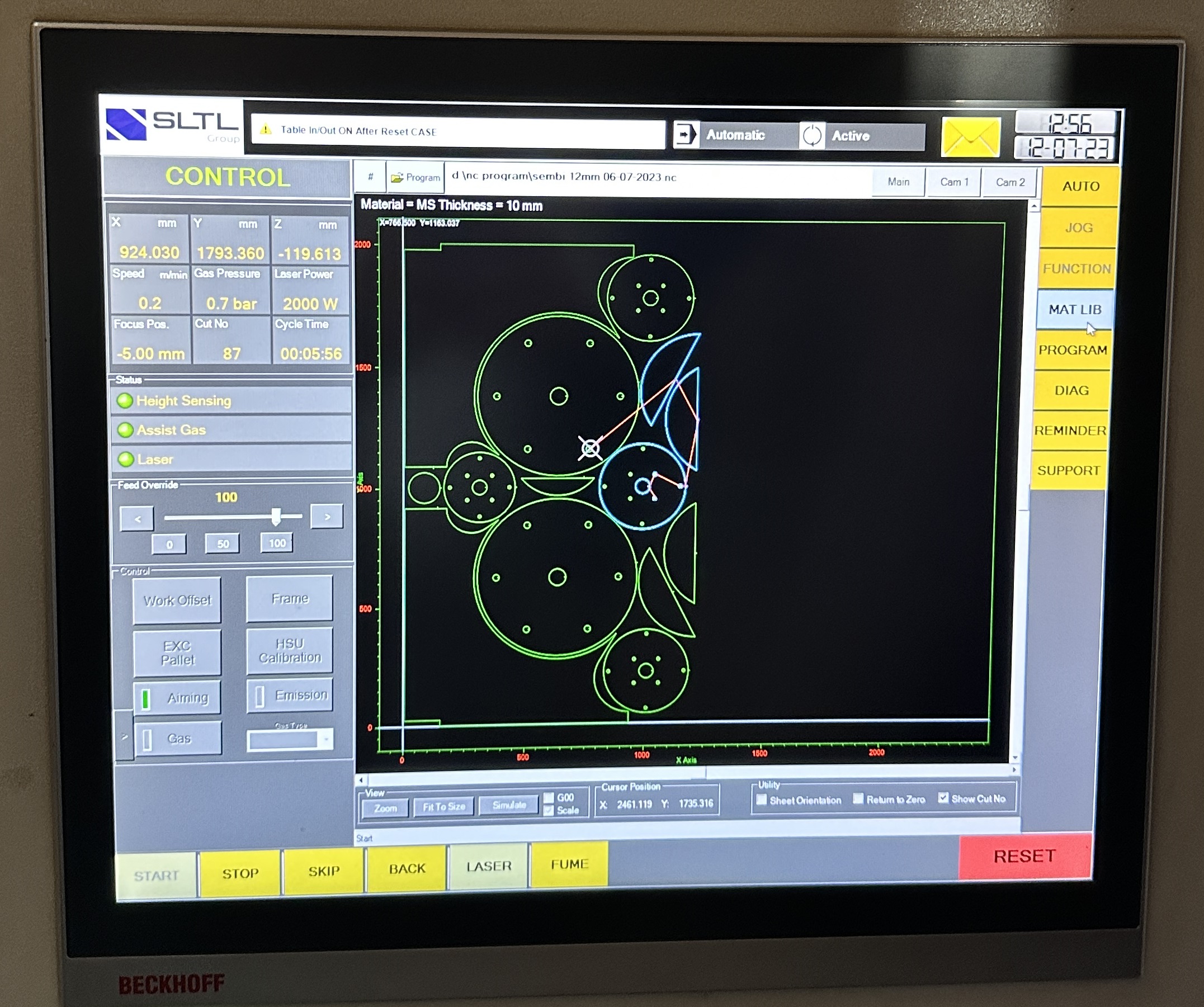

Laser Cutting Service:

– Utilize laser technology for precise and intricate cutting.

– High-speed cutting with exceptional accuracy and clean edges.

– Ideal for complex shapes and intricate designs.

– Suitable for a wide range of materials and thicknesses.

Waterjet Cutting Service:

– Utilize a high-pressure waterjet stream for cutting various materials.

– Capable of cutting metals, plastics, glass, and more.

– Provides clean and smooth edges without heat-affected zones.

– Suitable for materials with heat sensitivity or low melting points.

Plasma Cutting Service:

– Utilize plasma arc technology for fast and efficient cutting.

– Ideal for cutting thick metals with high precision.

– Offers excellent maneuverability and versatility.

– Suitable for industrial applications and heavy-duty metal cutting.

With our sheet metal services and cutting operations, we can accommodate a diverse range of projects and materials. Whether you require intricate laser cutting, precise waterjet cutting, or efficient plasma cutting, our experienced team ensures high-quality results. We work closely with our clients to understand their requirements and deliver sheet metal components that meet their specifications.