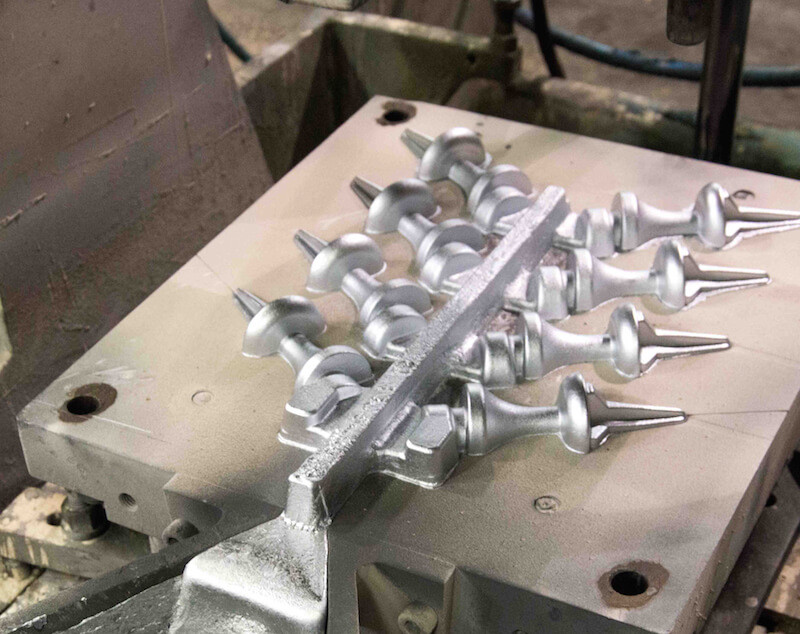

Casting

Machine-shop collaborates with die casting specialists who employ state-of-the-art die casting machinery and cutting-edge technology to provide top-notch, customized components to a diverse range of industries. Our service primarily centers on the two primary die casting methods: hot chamber casting and cold chamber casting. Both approaches have the capability to manufacture intricate-shaped parts with precise specifications and strong mechanical characteristics

Casting Processes

Die Cast Metal Materials

- Aluminium Die Casting

- Zinc Die Casting

What is Die Casting? Why us?

We offer a wide range of Die Casting services utilizing various techniques to meet your specific needs. Here are the highlighted bullet points about Die Casting:

- Die casting, a favored manufacturing method for high-volume, intricate metal parts, is prized for its adaptability, dependability, and precision.

- It significantly reduces or eliminates the need for secondary operations, although post-machining may be required for tighter tolerances.

- Post-processing options for die casting parts are as versatile as those for CNC-machined components.

- Similar to injection molding, die casting involves creating a mold tool (die) with one or more cavities.

- It is suitable for softer alloys like aluminum and zinc due to their lower melting points.

- Die casting entails injecting molten metal into the die cavity, which solidifies in the desired shape.

- Low- or high-pressure methods, using ladles or plungers, can be employed based on project requirements.

- Die casting excels at producing complex, precise components at exceptionally high production volumes.

- Modern techniques like squeeze casting and semi-solid metal casting yield top-quality parts across various industries.

- Aluminum dominates the die casting landscape, constituting about 80% of die cast components.

Our dedicated project managers meticulously assess each die casting project to provide tailored solutions, ensuring a seamless manufacturing process. Explore our capabilities and the die casting process