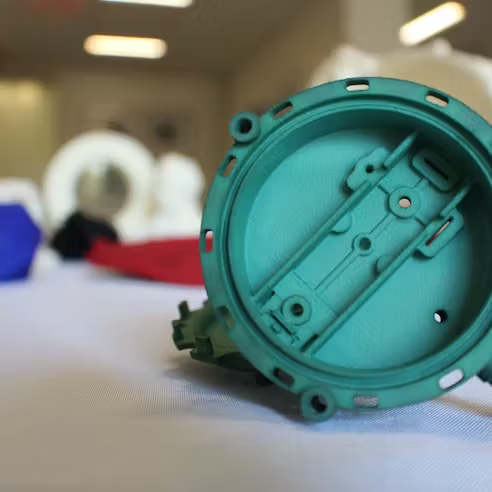

3D Printing

3D Printing offers rapid prototyping, customization, reduced time-to-market, cost-effectiveness, complex geometries, and sustainability.

3D Printing Processes

Precision 3D Printing Services Materials

- ABS

- Aluminium

- PETG

- PLA

- Nylon

- Polycarbonate

- Titanium

- SS 316

What is 3D Printing? Why us?

We offer a wide range of 3D printing services utilizing various techniques to meet your specific needs. Here are the highlighted bullet points for each technique:

Thermoplastic 3D Printing:

– Utilizes thermoplastic materials like PLA and ABS.

– Versatile, cost-effective, and easy to use.

– Suitable for a wide range of applications.

– Layer-by-layer approach for building objects.

Selective Laser Sintering (SLS) 3D Printing Service:

– Uses a high-power laser to selectively fuse nylon or polyamide powders.

– Capable of producing complex geometries with high accuracy.

– Ideal for functional prototypes and end-use parts.

– Provides durability and strength to printed objects.

HP Multi Jet Fusion (MJF) 3D Printing Service:

– Combines inkjet printing and fusing agent to build parts.

– Produces high-resolution parts with fine details and smooth surfaces.

– Well-suited for functional prototypes and small-batch production runs.

– Offers excellent dimensional accuracy and mechanical properties.

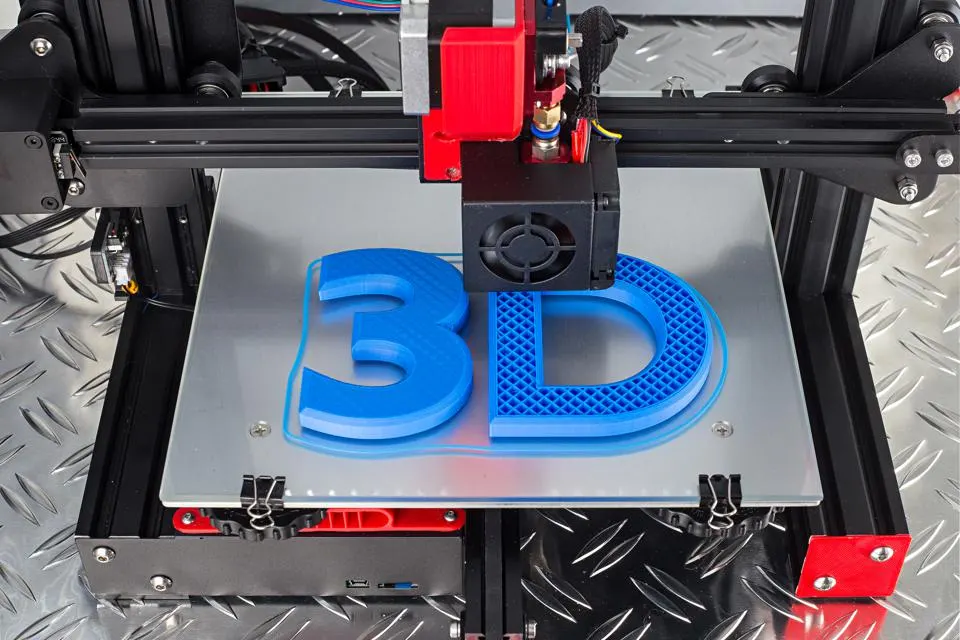

Fused Deposition Modeling (FDM) 3D Printing Service:

– Uses a heated nozzle to extrude thermoplastic filament layer by layer.

– Affordable and versatile with a wide range of material options.

– Ideal for prototyping, manufacturing tooling, and functional parts.

– Offers ease of use and a quick turnaround time.

In addition to these techniques, we also provide the following 3D printing services:

Thermoset 3D Printing:

– Uses materials that undergo a permanent chemical change when cured.

– Provides excellent mechanical properties and high temperature resistance.

– Suitable for functional prototypes and end-use parts.

PolyJet 3D Printing Service:

– Utilizes a jetting technology to simultaneously print multiple materials.

– Offers a high level of detail, smooth surfaces, and various material properties.

– Ideal for complex models, prototypes, and consumer products.

Stereolithography (SLA) 3D Printing Service:

– Utilizes a laser to cure liquid photopolymer resin into solid objects.

– Produces high-resolution, smooth, and detailed parts.

– Suitable for intricate designs, jewelry, and visual prototypes.

Production Photopolymer 3D Printing:

– Utilizes advanced resin materials for production-quality parts.

– Offers high-speed printing and excellent surface finish.

– Ideal for functional prototypes, end-use parts, and short-run production.

Nexa3D LSPc® Resin 3D Printing Service:

– Utilizes Nexa3D’s proprietary resin technology for rapid printing.

– Offers high throughput and exceptional surface quality.

– Suitable for industrial applications, functional prototypes, and concept modeling.

Carbon Digital Light Synthesis™ (DLS™) 3D Printing Service:

– Combines light and oxygen to rapidly produce parts with isotropic properties.

– Offers high-resolution prints with excellent mechanical properties.

– Suitable for end-use production parts, functional prototypes, and custom tooling.

Metal 3D Printing:

– Utilizes metal powders to create complex metal parts.

– Offers excellent strength, durability, and heat resistance.

– Ideal for aerospace, automotive, and medical applications.

Direct Metal Laser Sintering (DMLS) 3D Printing Service:

– Uses a high-power laser to fuse metal powders into solid parts.

– Provides excellent mechanical properties and complex geometries.

– Suitable for functional prototypes and end-use metal parts.

Metal Binder Jetting 3D Printing Service:

– Deposits metal powder and binds it with a liquid binder.

– Offers fast printing speeds and cost-effective production.

– Suitable for complex metal parts and large-scale production.

These are just a few examples of the 3D printing services we offer, each with its own unique advantages and applications. Our team of experts can help guide you in selecting the most suitable technique and material for your specific project requirements.